Note: If you click the picture it will enlarge. Fell free to copy it..

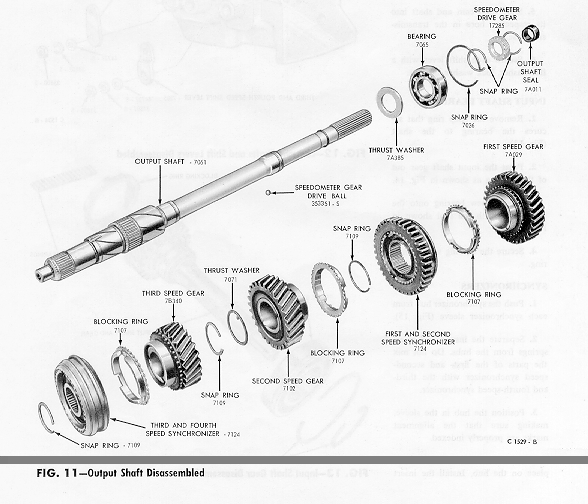

Using this exploded picture of a main shaft assembly from a 4 speed standard transmission, lets focus on the third and fourth speed synchronizer, the brass blocking ring and third gear. One item called the fork is missing.

The fork rides in a slot cut into the outer hub or slider as I will refer to it from now on, of the third and fourth synchronizer assembly. This allows the fork to fit in the slot and move the slider back and forth on the inner hub when you put the lever in third or fourth gear. We can not see 4th gear in this picture, so we will use third gear.

Looking closely at third gear one can see that there is a smooth shiny side on the left of the teeth on the gear. The smooth shiny side is tapered. The gear is made out of a hardened steel. The ring is made out of brass in this case, reason being is that the brass ring will wear before the steel gear, which costs a lot more than a brass ring.

The brass blocking ring is internally tapered to almost match the taper on the gear. It has to have a bit of a different taper than the gear or it won’t work, as in, slow the gear down, or it is worn out.

When the driver exerts pressure on the shift lever to put the vehicle into third gear (or the gear selected), the fork which is inserted into the slot cut in the slider pushes the slider against the brass blocking ring, in turn the brass ring which we know is tapered on the inside pushes against the shiny taper of the gear. Because the degrees of taper are different, the brass slows down the third gear (in this case) and matches the speed the third gear turns to the same speed that 4th gear is turning. Because both gears are turning at the same speed now, we can get a clean smooth shift.

This synchronizer activity works much the same way on all of the gears in a standard transmission.

In fact, there are different types of blocking rings and materials that blocking rings come in, however the way they work is the same.

I will caution you that it is vitally important to know what type of synchronizer rings are in your transmission. Why? It is paramount to the function and life span of your standard transmission to use to proper standard transmission lubrication.

I hope this sheds a little light on how the gears in a standard transmission manage not to grind and clash when you shift.

Check out more function and theory of standard transmissions and automatic transmissions (for that matter) on the GotTranmsissions.com blog. Good luck and enjoy. BTW, feel free to add a comment or correct me if I am incorrect or vague in any way.